Dampney Engineered Coatings

LASTER/CASTOR CORPORATION – AUTHORIZED DISTRIBUTOR

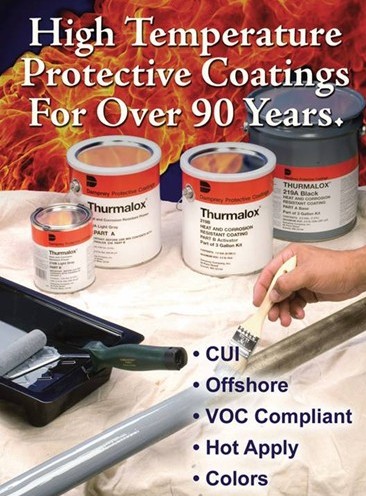

Dampney Company high performance coatings feature Thurmalox Heat-Resistant finishes for metal structures, refinery stacks, heat exchangers, piping, turbines, process vessels and tanks. These coating products feature a heat-activated catalyst for application on high-temperature surfaces up to 1200°F. Dampney serves the refining, petro chemical, chemical processing, oil & gas, pipeline, power, OEM, pulp & paper, and materials processing markets. THURMALOX High Temperature Industrial Protective Coatings – for metal structures subjected to high temperatures and corrosive environments.

BRAND NEW ITEM

NOW AVAILABLE FROM LASTER/CASTOR COATINGS:

CLEMCO INTERNAL PIPE CLEANING EQUIPMENT.

SEE IT NOW > > CLEMCO PIPE CLEANING BROCHURE

View Dampney Coatings Coverage Chart >> CHART <<

Thurmalox® 200

Heat resistant coatings, color stable ambient to 500F (260C)

>>Single Component Heat Resistant Coatings

>> PRODUCT DATA SHEET

REQUEST A >>QUICK-QUOTE<< HERE

Thurmalox® 200C

Air Dry Series VOC Compliant Silicone Coatings Heat Resistant to 500°F.

>>Heat Resistant Silicone Coatings

>> PRODUCT DATA SHEET

REQUEST A >>QUICK-QUOTE<< HERE

Thurmalox® 210

Zinc silicone primer, heat resistant ambient to 500F (260C)

>>Zinc Silicone Primers

>> PRODUCT DATA SHEET

REQUEST A >>QUICK-QUOTE<< HERE

Thurmalox® 210C

VOC Compliant Zinc silicone primer heat resistant to 500F

>>Zinc Silicone Heat Resistant Primer

>> PRODUCT DATA SHEET

REQUEST A >>QUICK-QUOTE<< HERE

Thurmalox® 217

Finish coating over Thurmalox 218/219 that will not be insulated

>>Thurmalox® 217 Finish Coating

>> PRODUCT DATA SHEET

REQUEST A >>QUICK-QUOTE<< HERE

Thurmalox® 218

For under insulation, boiling water immersion grade, apply directly to hot steel up to 350F(176C) with service temperatures up to 450F (232C)

>>Polymeric Coating

>> PRODUCT DATA SHEET

REQUEST A >>QUICK-QUOTE<< HERE

Thurmalox® 219

For under insulation, boiling water immersion grade, apply directly to hot steel up to 350F(176C) with service temperatures up to 450F (232C)

>>Polymeric Coating

>> PRODUCT DATA SHEET

REQUEST A >>QUICK-QUOTE<< HERE

Thurmalox® 225HD

VOC compliant, high build coating from 300ºF to 1000ºF (148ºC to 538ºC)

>>Corrosion Inhibitive Coating

>> PRODUCT DATA SHEET

REQUEST A >>QUICK-QUOTE<< HERE

Thurmalox® 230

Heat resistant coatings, color stable ambient to 1000°F (538°C)

>>Color Stable Heat Resistant Coating

>> PRODUCT DATA SHEET

REQUEST A >>QUICK-QUOTE<< HERE

Thurmalox® 230C

Heat resistant coatings, color stable ambient to 1000°F (538°C)

>>Color Stable Heat Resistant Coating

>> PRODUCT DATA SHEET

REQUEST A >>QUICK-QUOTE<< HERE

Thurmalox® 240

Heat resistant coatings from 1100F to 1400F (593C to 760C)

>>High Temperature Silicon Ceramic Coating

>> PRODUCT DATA SHEET

REQUEST A >>QUICK-QUOTE<< HERE

Thurmalox® 242

Heat resistant coatings from 1100F to 1600F (593C to 871C)

>>Silicone Ceramic Coating

>> PRODUCT DATA SHEET

REQUEST A >>QUICK-QUOTE<< HERE

Thurmalox® 242C-02

Black Silicone Industrial Coating

>>Silicone Black Industrial Coating

>> PRODUCT DATA SHEET

REQUEST A >>QUICK-QUOTE<< HERE

Thurmalox® 245

Silicone zinc dust primer – heat resistance from 500°F to 1200°F (260°C to 648°C)

>>Silicone Zinc Dust Primer

>> PRODUCT DATA SHEET

REQUEST A >>QUICK-QUOTE<< HERE

Thurmalox® 245C

VOC Compliant Silicone zinc dust primer – heat resistance from 500°F to 1200°F (260°C to 648°C)

>>VOC Compliant Silicone zinc dust primer

>> PRODUCT DATA SHEET

REQUEST A >>QUICK-QUOTE<< HERE

Thurmalox® 250

Thurmalox 250 Selective Black, silicone-based paint which collects heat more efficiently than ordinary black paint and resists outgassing to 400F (Available in 1-gal, 5-gal, Quarts & 13 oz. Spray Cans for easy touchup)

>>Solar Collector Coating

>> PRODUCT DATA SHEET

REQUEST A >>QUICK-QUOTE<< HERE

Thurmalox® 260

Heat and Corrosion Resistant to 500F. Standard and Custom Colors Apply Directly to Hot Steel)

>>Heat and Corrosion Resistant Coating

>> PRODUCT DATA SHEET

REQUEST A >>QUICK-QUOTE<< HERE

Thurmalox® 2600

High build coating, ambient to 600°F (316°C), for air pollution control equipment

>>High Build Coating

>> PRODUCT DATA SHEET

REQUEST A >>QUICK-QUOTE<< HERE

Thurmalox® 260C

Heat and Corrosion Resistant to 500F. Standard and Custom Colors Apply Directly to Hot Steel

>>Heat and Corrosion Resistant Coating

>> PRODUCT DATA SHEET

REQUEST A >>QUICK-QUOTE<< HERE

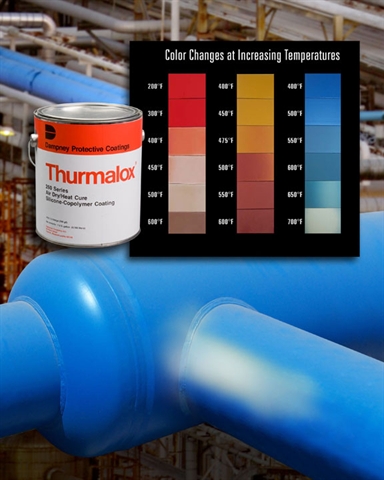

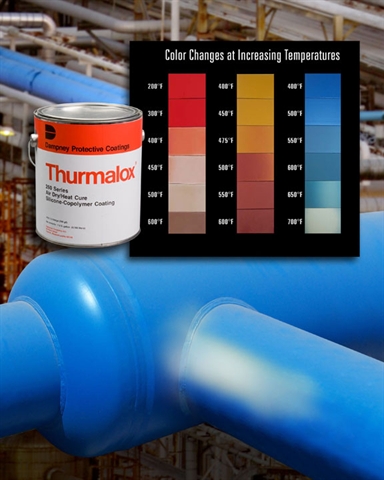

Thurmalox® 260C TIC

Temperature indicating coatings with color change

>>Temperature Indicating Coating

>> PRODUCT DATA SHEET

REQUEST A >>QUICK-QUOTE<< HERE

Thurmalox® 884 TIC

Temperature indicating coatings with color change

>>Temperature Indicating Coating

>>Temperatures & Colors Chart

REQUEST A >>QUICK-QUOTE<< HERE

Thurmalox® 2655

High Temperature Silicone Caulking Compound

>>High Temperature Silicone Caulk

>> PRODUCT DATA SHEET

REQUEST A >>QUICK-QUOTE<< HERE

Thurmalox® 280

High temperature aluminum coating, ambient to 1200°F (649°C)

>>High Temperature Aluminum Coating

>> PRODUCT DATA SHEET

REQUEST A >>QUICK-QUOTE<< HERE

Thurmalox® 280C

280C Aluminum Air Dry VOC Compliant Silicone Coating Heat Resistance 500°F – 1200°F

>>VOC Compliant Silicone Coating

>> PRODUCT DATA SHEET

REQUEST A >>QUICK-QUOTE<< HERE

Thurmalox® 70

Prevents chloride induced external stress corrosion cracking from cryogenic to 1000F

>>Protective Coating for Stainless Steel

>> PRODUCT DATA SHEET

REQUEST A >>QUICK-QUOTE<< HERE

Thurmalox® 70C

VOC Compliant stainless steel coating prevents chloride induced external stress corrosion cracking to 1000F

>>Stainless Steel Coating

>> PRODUCT DATA SHEET

REQUEST A >>QUICK-QUOTE<< HERE

Thurmalox® 837

Inorganic Hybrid Zinc Rich Protective High Temperature Primer

>>Inorganic Hybrid Zinc Rich Protective High Temperature Primer

>> PRODUCT DATA SHEET

Use our Exlusive Product Selector

>>QUICK-QUOTE<<

form for the above Thurmalox coatings.

OTHER DAMPNEY PRODUCT LINES

- THURMALOX High Temperature Industrial Protective Coatings – for metal structures subjected to high temperatures and corrosive environments.

- THURMALOX High Temperature Protective Coatings for the OEM Market – for metal products and applications subjected to high temperatures and various environments

- EPODUR 100% Solid Novolac Systems – for secondary containment, flooring and concrete restorations.

- APEXIOR Protective Coatings – for water-side corrosion prevention of steam generating equipment and auxiliaries.

- DYMACRYL Water Repellent Masonry Stains – for concrete and masonry surfaces.

- ELASTOID High Build Elastomeric Rubber Coatings.

- ENDCOR Corrosion Resistant Coatings – for general industrial maintenance.

- EPODUR High Solids Epoxy Coatings – for long-term, heavy duty protection in aggressive chemical, industrial, and marine environments.

Click here to CONTACT US

or

call Toll Free: 800.414.4120

Oklahoma Office:

Laster/Castor Corporation

1101 N. 161st East Avenue

Tulsa, OK 74116-4000

918.234.7777

918.234.4120 Fax